Toyota Land Cruiser Service ManualSuspension & Axle

Toyota Land Cruiser Service ManualSuspension & Axle

Front wheel alignment

Front wheel alignment

INSPECTION

1. MEASURE VEHICLE HEIGHT

Vehicle height:

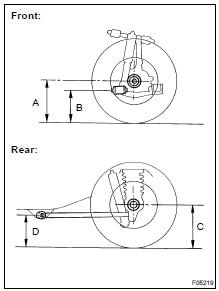

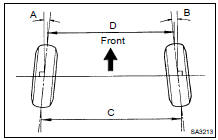

Measuring points: A: Ground clearance of spindle center B: Ground clearance of lower suspension arm front bolt center C: Ground clearance of rear axle shaft center D: Ground clearance of lower control arm front bolt center

NOTICE: Before inspecting the wheel alignment, adjust the vehicle height to the specified value.

If the vehicle height is not the specified value, try to adjust it by pushing down on or lifting the body.

2. INSTALL CAMBER-CASTER-KINGPIN GAUGE OR POSITION VEHICLE ON WHEEL ALIGNMENT TESTER

Follow the specific instructions of the equipment manufacturer.

3. INSPECT CAMBER, CASTER AND STEERING AXIS INCLINATION

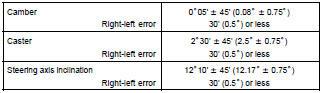

Camber, caster and steering axis inclination:

If the steering axis inclination is not within the specified value, after the camber and caster have been correctly adjusted, recheck the steering knuckle and front wheel for bearing or looseness.

4. ADJUST CAMBER AND CASTER

NOTICE: After the camber has been adjusted, inspect the toe-in.

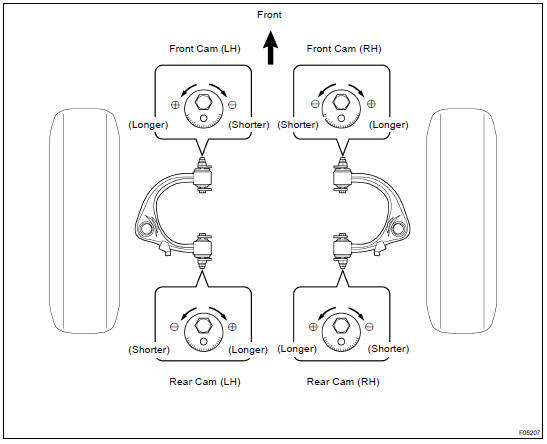

(a) Loosen the front and/or rear adjusting cam nuts.

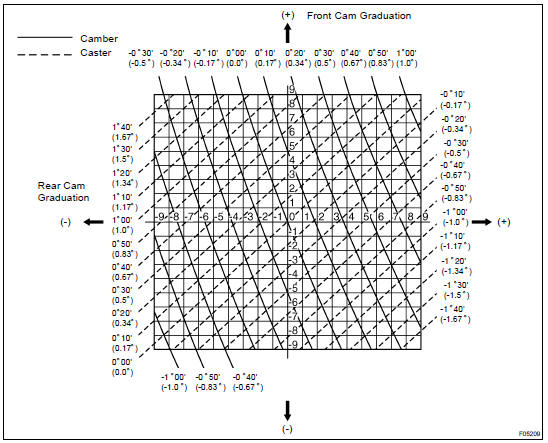

(b) Adjust the camber and caster by front and/or rear adjusting cams.

HINT: Try to adjust the camber and caster to the center of the specified value.

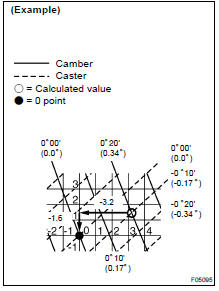

(c) How to read adjustment chart (using examples).

- Measure the present alignment.

Camber: -015' (-0.25) Caster: 240' (2.67)

- Mark the difference between the standard value (A) and the measured value (B) on the adjustment chart.

Standard value: Camber: 005' (0.08) Caster: 230' (2.5) Formula: A - B = C Camber: 005' - (-015') = 020' Caster: 230' - 240' = -010'

- As shown in the chart, read the distances from the marked point to 0 point, and adjust the front and/or rear adjusting cams accordingly.

Front cam: - (Shorter) 1.6 Rear cam: - (Shorter) 3.2

(d) Torque the front and/or rear adjusting cam nuts.

Torque: 98 N·m (1,000 kgf·cm, 72 ft·lbf)

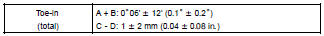

5. INSPECT TOE-IN

Toe-in:

If the toe-in is not within the specified value, adjust it at the rack ends.

6. ADJUST TOE-IN

(a) Check or adjust the lengths of the rack ends, then adjust the toe-in.

Rack end length difference: 3.0 mm (0.118 in.) or less

(b) Remove the boot clamps.

(c) Loosen the tie rod end lock nuts.

(d) Turn the right and left rack ends by an equal amount to adjust the toe-in.

HINT: Try to adjust the toe-in to the center of the specified value.

(e) Tighten the tie rod end lock nuts.

Torque: 55 N·m (560 kgf·cm, 41 ft·lbf)

(f) Place the boots on the seats and install the clamps.

HINT: Make sure that the boots are not twisted.

(g) Perform the zero point calibration of yaw rate and deceleration sensor (DI-505 ).

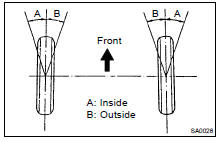

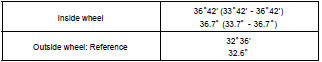

7. INSPECT AND ADJUST WHEEL ANGLE

(a) Turn the steering wheel fully, and measure the turning angle.

Wheel turning angle:

If the right and left inside wheel angles differ from the specified value, check the right and left rack end lengths.

(b) When toe-in is normal after inspection, adjust wheel angle with the knuckle stopper bolt of the lower suspension arm.

Torque: 44 N·m (450 kgf·cm, 32 ft·lbf)