Toyota Land Cruiser Service ManualStarting » Starter

Toyota Land Cruiser Service ManualStarting » Starter

Inspection

Inspection

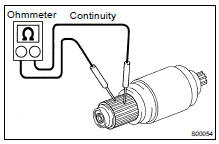

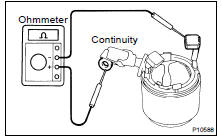

1. INSPECT COMMUTATOR FOR OPEN CIRCUIT

Using an ohmmeter, check that there is continuity between the segments of the commutator.

If there is no continuity between any segment, replace the armature.

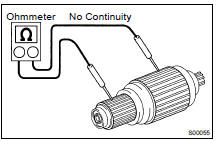

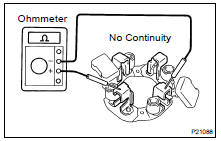

2. INSPECT COMMUTATOR FOR GROUND

Using an ohmmeter, check that there is no continuity between the commutator and armature coil core.

If there is continuity, replace the armature.

3. INSPECT COMMUTATOR FOR DIRTY AND BURNT SURFACE

If the surface is dirty or burnt, correct it with sandpaper (No.400) or on a lathe.

4. INSPECT COMMUTATOR CIRCLE RUNOUT

(a) Place the commutator on V-blocks.

(b) Using a dial indicator the circle runout.

Maximum circle runout: 0.05 mm (0.0020 in.)

If the circle runout is greater than maximum, correct it on a lathe.

5. INSPECT COMMUTATOR DIAMETER

Using vernier calipers, measure the commutator diameter.

Standard diameter: 35.0 mm (1.378 in.) Minimum diameter: 34.0 mm (1.339 in.)

If the diameter is less than minimum, replace the armature.

6. INSPECT UNDERCUT DEPTH

Check that the undercut depth is clean and free of foreign materials.

Smooth out the edge.

Standard undercut depth: 0.7 mm (0.028 in.) Minimum undercut depth: 0.2 mm (0.008 in.)

If the undercut depth is less than minimum, correct it with a hacksaw blade.

7. INSPECT FIELD COIL FOR OPEN CIRCUIT

Using an ohmmeter, check that there is continuity between the lead wire and field coil brush lead.

If there is no continuity, replace the field frame.

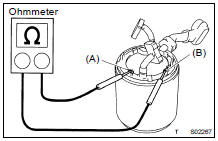

8. INSPECT SHUNT COIL FOR OPEN CIRCUIT

Using an ohmmeter, measure the resistance between shunt coil terminals (A) and (B).

Resistance: 1.5 - 1.9 W at 20C (68F)

If the resistance is not as specified, replace the field frame.

9. INSPECT BRUSH LENGTH

Using vernier calipers, measure the brush length.

Standard length: 15.0 mm (0.591 in.) Minimum length: 9.0 mm (0.354 in.)

If the length is less than minimum, replace the brush holder and field frame.

10. INSPECT BRUSH SPRING LOAD

Using a pull scale, measure the spring load by pulling the spring from the brush until they are separated.

Standard spring installed load: 21.5 - 27.5 N (2.2 - 2.8 kgf, 4.8 - 6.2 lbf) Minimum spring installed load: 12.7 N (1.3 kgf, 2.9 lbf)

If the installed load is less than minimum, replace the brush springs.

11. INSPECT BRUSH HOLDER INSULATION

Using an ohmmeter, check that there is no continuity between the positive (+) and negative (-) brush holders.

If there is continuity, repair or replace the brush holder.

12. INSPECT GEAR TEETH

Check the gear teeth on the pinion gear, idle gear and the clutch assembly for wear or damage.

If any damage is found, replace the gear or clutch assembly, and also check the drive plate ring gear for wear or damage.

13. INSPECT CLUTCH PINION GEAR

Rotate the pinion gear clockwise, and check that it turns freely.

Check that it locks by rotating the pinion gear counterclockwise.

If necessary, replace the clutch assembly.

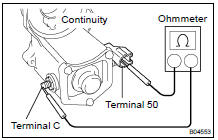

14. DO PULL-IN COIL OPEN CIRCUIT TEST

Using an ohmmeter, check that there is continuity between terminals 50 and C.

If there is no continuity, replace the magnetic switch.

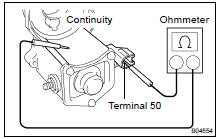

15. DO HOLD-IN COIL OPEN CIRCUIT TEST

Using an ohmmeter, check that there is continuity between terminal 50 and the switch body.

If there is no continuity, replace the magnetic switch.