Toyota Land Cruiser Owners ManualVehicle

specifications » Specifications

Toyota Land Cruiser Owners ManualVehicle

specifications » Specifications

Tire information

Tire information

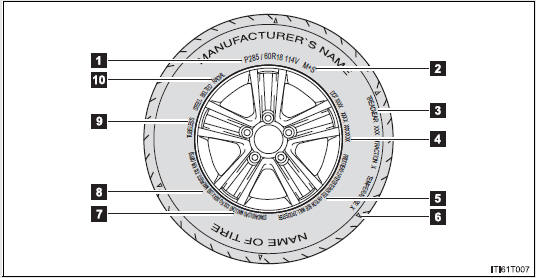

Typical tire symbols

- Tire size

- Summer tire or all season tire

An all season tire has “M+S” on the sidewall. A tire not marked “M+S” is a summer tire.

- Uniform tire quality grading

For details, see “Uniform Tire Quality Grading” that follows.

- DOT and Tire Identification Number (TIN)

- Tire ply composition and materials

Plies are layers of rubber-coated parallel cords. Cords are the strands which form the plies in a tire.

- Location of treadwear indicators

- Load limit at maximum cold tire inflation pressure

- Maximum cold tire inflation pressure

This means the pressure to which a tire may be inflated.

- TUBELESS or TUBE TYPE

A tubeless tire does not have a tube and air is directly filled in the tire. A tube type tire has a tube inside the tire and the tube maintains the air pressure.

- Radial tires or bias-ply tires

A radial tire has RADIAL on the sidewall. A tire not marked RADIAL is a bias-ply tire.

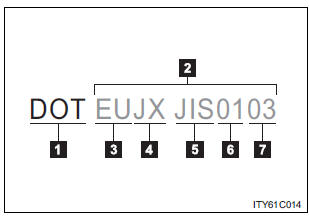

Typical DOT and tire identification number (TIN)

- DOT symbol*

- Tire Identification Number (TIN)

- Tire manufacturer’s identification mark

- Tire size code

- Manufacturer’s optional tire type code (3 or 4 letters)

- Manufacturing week

- Manufacturing year

*:The DOT symbol certifies that the tire conforms to applicable Federal Motor Vehicle Safety Standards.

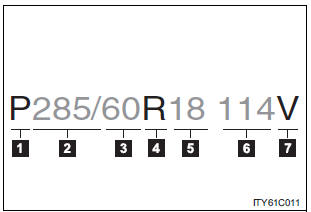

Tire size

- Typical tire size information

The illustration indicates typical tire size.

- Tire use (P = Passenger car, T = Temporary use)

- Section width (millimeters)

- Aspect ratio (tire height to section width)

- Tire construction code (R = Radial, D = Diagonal)

- Wheel diameter (inches)

- Load index (2 or 3 digits)

- Speed symbol (alphabet with one letter)

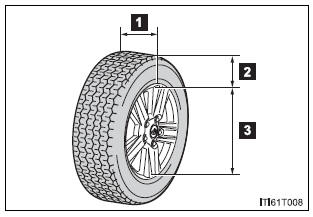

- Tire dimensions

- Section width

- Tire height

- Wheel diameter

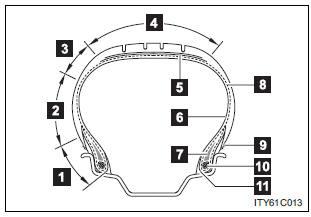

Tire section names

- Bead

- Sidewall

- Shoulder

- Tread

- Belt

- Inner liner

- Reinforcing rubber

- Carcass

- Rim lines

- Bead wires

- Chafer

Uniform Tire Quality Grading

This information has been prepared in accordance with regulations issued by the National Highway Traffic Safety Administration of the U.S.A. Department of Transportation.

It provides the purchasers and/or prospective purchasers of Toyota vehicles with information on uniform tire quality grading.

Your Toyota dealer will help answer any questions you may have as you read this information.

- DOT quality grades

All passenger vehicle tires must conform to Federal Safety Requirements in addition to these grades. Quality grades can be found where applicable on the tire sidewall between tread shoulder and maximum section width.

For example: Treadwear 200 Traction AA Temperature A

- Treadwear

The treadwear grade is a comparative rating based on the wear rate of the tire when tested under controlled conditions on a specified government test course.

For example, a tire graded 150 would wear one and a half (1 - 1/2) times as well on the government course as a tire graded 100.

The relative performance of tires depends upon the actual conditions of their use, however, and may depart significantly from the norm due to variations in driving habits, service practices and differences in road characteristics and climate.

- Traction AA, A, B, C

The traction grades, from highest to lowest, are AA, A, B and C, and they represent the tire’s ability to stop on wet pavement as measured under controlled conditions on specified government test surfaces of asphalt and concrete.

A tire marked C may have poor traction performance.

Warning: The traction grade assigned to this tire is based on braking (straight ahead) traction tests and does not include cornering (turning) traction.

- Temperature A, B, C

The temperature grades are A (the highest), B, and C, representing the tire’s resistance to the generation of heat and its ability to dissipate heat when tested under controlled conditions on a specified indoor laboratory test wheel.

Sustained high temperature can cause the material of the tire to degenerate and reduce tire life, and excessive temperature can lead to sudden tire failure.

The grade C corresponds to a level of performance which all passenger car tires must meet under the Federal Motor Vehicle Safety Standard No. 109.

Grades B and A represent higher levels of performance on the laboratory test wheel than the minimum required by law.

Warning: The temperature grades for this tire are established for a tire that is properly inflated and not overloaded.

Excessive speed, underinflation, or excessive loading, either separately or in combination, can cause heat buildup and possible tire failure.

Glossary of tire terminology

| Tire related term | Meaning |

| Cold tire inflation pressure | Tire pressure when the vehicle has been parked for three hours or more, or has not been driven more than 1 mile or 1.5 km under that condition |

| Maximum inflation pressure | The maximum cold inflated pressure to which a tire may be inflated, shown on the sidewall of the tire |

| Recommended inflation pressure | Cold tire inflation pressure recommended by a manufacturer. |

| Accessory weight | The combined weight (in excess of those standard items which may be replaced) of transmission, power steering, power brakes, power windows, power seats, radio and heater, to the extent that these items are available as factoryinstalled equipment (whether installed or not) |

| Curb weight | The weight of a motor vehicle with standard equipment, including the maximum capacity of fuel, oil and coolant, and if so equipped, air conditioning and additional weight optional engine |

| Maximum loaded vehicle weight | The sum of:

|

| Normal occupant weight | 150 lb. (68 kg) times the number of occupants specified in the second column of Table 1* that follows |

| Occupant distribution | Distribution of occupants in a vehicle as specified in the third column of Table 1* below |

| Production options weight | The combined weight of installed regular production options weighing over 5 lb. (2.3 kg) in excess of the standard items which they replace, not previously considered in curb weight or accessory weight, including heavy duty brakes, ride levelers, roof rack, heavy duty battery, and special trim |

| Rim | A metal support for a tire or a tire and tube assembly upon which the tire beads are seated |

| Rim diameter (Wheel diameter) | Nominal diameter of the bead seat |

| Rim size designation | Rim diameter and width |

| Rim type designation | The industry manufacturer’s designation for a rim by style or code |

| Rim width | Nominal distance between rim flanges |

| Vehicle capacity weight (Total load capacity) | The rated cargo and luggage load plus 150 lb.

(68 kg) times the vehicle’s designated seating capacity |

| Vehicle maximum load on the tire | The load on an individual tire that is determined by distributing to each axle its share of the maximum loaded vehicle weight, and dividing by two |

| Vehicle normal load on the tire | The load on an individual tire that is determined by distributing to each axle its share of curb weight, accessory weight, and normal occupant weight (distributed in accordance with Table 1* below), and dividing by two |

| Weather side | The surface area of the rim not covered by the inflated tire |

| Bead | The part of the tire that is made of steel wires, wrapped or reinforced by ply cords and that is shaped to fit the rim |

| Bead separation | A breakdown of the bond between components in the bead |

| Bias ply tire | A pneumatic tire in which the ply cords that extend to the beads are laid at alternate angles substantially less than 90 degrees to the centerline of the tread |

| Carcass | The tire structure, except tread and sidewall rubber which, when inflated, bears the l |

| Chunking | The breaking away of pieces of the tread or sidewall |

| Cord | The strands forming the plies in the tire |

| Cord separation | The parting of cords from adjacent rubber compounds |

| Cracking | Any parting within the tread, sidewall, or innerliner of the tire extending to cord material |

| CT | A pneumatic tire with an inverted flange tire and rim system in which the rim is designed with rim flanges pointed radially inward and the tire is designed to fit on the underside of the rim in a manner that encloses the rim flanges inside the air cavity of the tire |

| Extra load tire | A tire designed to operate at higher loads and at higher inflation pressures than the corresponding standard tire |

| Groove | The space between two adjacent tread ribs |

| Innerliner | The layer(s) forming the inside surface of a tubeless tire that contains the inflating medium within the tire |

| Innerliner separation | The parting of the innerliner from cord material in the carcass |

| Intended outboard sidewall |

|

| Light truck (LT) tire | A tire designated by its manufacturer as primarily intended for use on lightweight trucks or multipurpose passenger vehicles |

| Load rating | The maximum load that a tire is rated to carry for a given inflation pressure |

| Maximum load rating | The load rating for a tire at the maximum permissible inflation pressure for that tire |

| Maximum permissible inflation pressure | The maximum cold inflation pressure to which a tire may be inflated |

| Measuring rim | The rim on which a tire is fitted for physical dimension requirements |

| Open splice | Any parting at any junction of tread, sidewall, or innerliner that extends to cord material |

| Outer diameter | The overall diameter of an inflated new tire |

| Overall width | The linear distance between the exteriors of the sidewalls of an inflated tire, including elevations due to labeling, decorations, or protective bands or ribs |

| Passenger car tire | A tire intended for use on passenger cars, multipurpose passenger vehicles, and trucks, that have a gross vehicle weight rating (GVWR) of 10,000 lb. or less |

| Ply | A layer of rubber-coated parallel cords |

| Ply separation | A parting of rubber compound between adjacent plies |

| Pneumatic tire | A mechanical device made of rubber, chemicals, fabric and steel or other materials, that, when mounted on an automotive wheel, provides the traction and contains the gas or fluid that sustains the load |

| Radial ply tire | A pneumatic tire in which the ply cords that extend to the beads are laid at substantially 90 degrees to the centerline of the tread |

| Reinforced tire | A tire designed to operate at higher loads and at higher inflation pressures than the corresponding standard tire |

| Section width | The linear distance between the exteriors of the sidewalls of an inflated tire, excluding elevations due to labeling, decoration, or protective bands |

| Sidewall | That portion of a tire between the tread and bead |

| Sidewall separation | The parting of the rubber compound from the cord material in the sidewall |

| Snow tire | tire that attains a traction index equal to or

greater than 110, compared to the ASTM E-

1136 Standard Reference Test Tire, when

using the snow traction test as described in

ASTM F-1805-00, Standard Test Method for

Single Wheel Driving Traction in a Straight Line

on Snow-and Ice-Covered Surfaces, and which

is marked with an Alpine Symbol ( ) on at

least one sidewall

) on at

least one sidewall |

| Test rim | The rim on which a tire is fitted for testing, and may be any rim listed as appropriate for use with that tire |

| Tread | That portion of a tire that comes into contact with the road |

| Tread rib | A tread section running circumferentially around a tire |

| Tread separation | Pulling away of the tread from the tire carcass |

| Treadwear indicators (TWI) | The projections within the principal grooves designed to give a visual indication of the degrees of wear of the tread |

| Wheel-holding fixt | The fixture used to hold the wheel and tire assembly securely during testing |

*: Table 1 - Occupant loading and distribution for vehicle normal load for various designated seating capacities

| Designated seating capacity, Number of occupants | Vehicle normal load, Number of occupants | Occupant distribution in a normally loaded vehicle |

| 2 through 4 | 2 | 2 in front |

| 5 through 10 | 3 | 2 in front, 1 in second seat |

| 11 through 15 | 5 | 2 in front, 1 in second seat, 1 in third seat, 1 in fourth seat |

| 16 through | 7 | 2 in front, 2 in second seat, 2 in third seat, 1 in fourth seat |