Toyota Land Cruiser Service ManualSuspension & Axle » Rear differential carrier (w/ LSD)

Toyota Land Cruiser Service ManualSuspension & Axle » Rear differential carrier (w/ LSD)

Reassembly

Reassembly

HINT:

- When reusing the side gear, thrust washers and clutch plates, skip the STEP 1.

- Using a shop rag, clean off any foreign object from the parts.

- Apply all of the sliding and rotating surfaces with LSD oil.

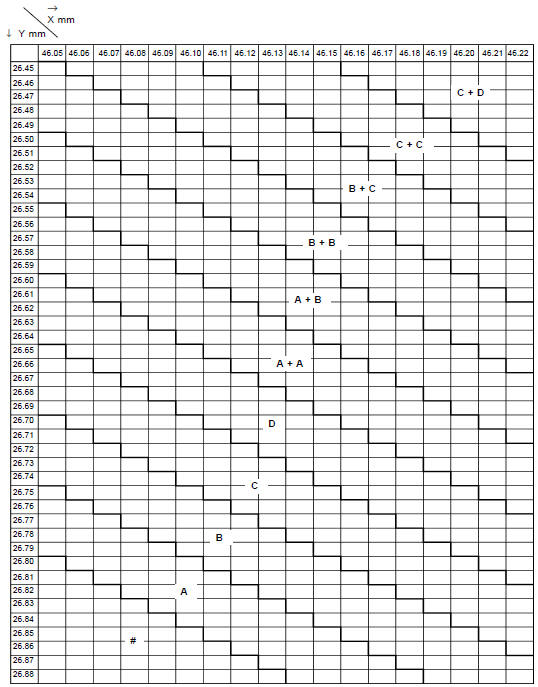

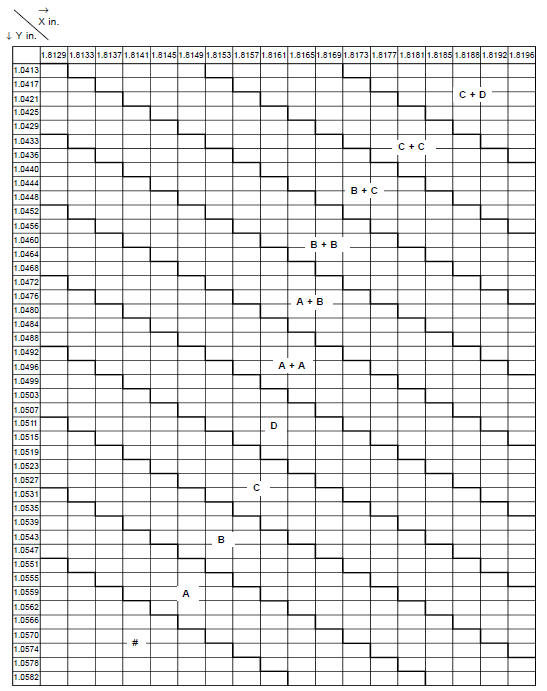

1. SELECT ADJUSTING SHIM

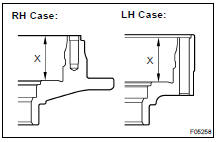

(a) Measure the RH and LH differential case dimensions "X", as shown in the illustration.

(b) Install the thrust washers and clutch plates on the side gear.

(c) Using SST to press down the thrust washers and clutch plates with about pressure of 10 kgf (22 lbf), measure dimension "Y", as shown in the illustration.

SST 09649-17010

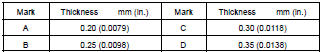

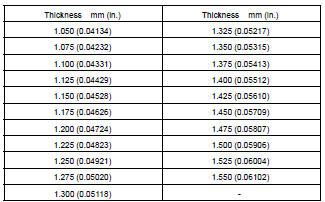

(d) Referring to the following selection table on the next page, select the proper adjusting shim.

Adjust shim thickness = X - Y - 19.08 mm (0.7511 in.)

#: Reassemble another type shim or check the backlash after assembling A shim.

#: Reassemble another type shim or check the backlash after assembling A shim.

Adjust shim thickness:

2. CHECK SIDE GEAR BACKLASH

(a) Install the thrust washers, clutch plates and adjusting shim to side gear.

HINT: Install the adjusting shim with its surface having no oil groove facing to the differential case side.

(b) Install the side gear to the differential case.

(c) Install the 4 pinion gears and thrust washers to the spider.

(d) Align the spring retainer holes with the straight pins and install the retainer.

(e) Install the spider to the differential case.

HINT: Install the spider to the differential case tightly and do not move the spring retainer.

(f) Using a dial indicator, measure the side gear backlash while holding the side gear and spider.

Backlash: 0.02 - 0.15 mm (0.0008 - 0.0059 in.)

HINT:

- Measure at all 4 locations.

- Measure the backlash at the RH and LH differential cases.

If the backlash is not within the specified value, select the adjusting shim.

3. ASSEMBLE DIFFERENTIAL CASE

(a) Reinstall the spider to the LH differential case.

HINT: Install the spider to the LH differential case tightly and do not move the spring retainer.

(b) Install the compression spring and RH spring retainer.

(c) Install the RH side gear.

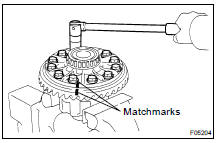

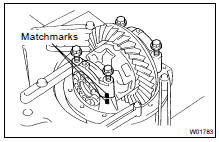

(d) Align the matchmarks and assemble the RH and LH differential cases.

HINT:

- Be careful not to drop the side gear.

- Check the pinion and side gear alignment.

(e) Tighten the 8 bolts uniformly, a little at a time.

Torque: 47 N·m (480 kgf·cm, 35 ft·lbf)

4. INSTALL SIDE BEARING

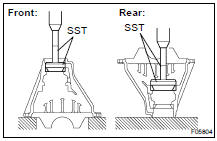

(a) Using SST and a press, install the RH side bearing on the differential case.

SST 09710-30050, 09950-70010 (09951-07100)

(b) Using SST and a press, install the LH side bearing on the differential case.

SST 09710- 30050, 09950- 60010 (09951- 00480), 09950-70010 (09951-07100)

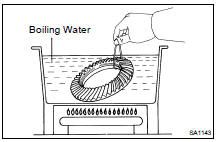

5. INSTALL RING GEAR ON DIFFERENTIAL CASE

(a) Clean the threads of the bolts and differential case with the white gasoline.

(b) Clean the contact surfaces of the differential case and ring gear.

(c) Heat the ring gear to about 100 C (212 F) in boiling water.

(d) Carefully take the ring gear out of the boiling water.

(e) After the moisture on the ring gear has completely evaporated, quickly install the ring gear to the differential case.

(f) Align the matchmarks on the ring gear and differential case.

(g) Temporarily install the 12 set bolts.

(h) After the ring gear has cooled down enough, torque the 12 set bolts to which thread lock has been applied.

Thread lock: Part No. 08833-00100, THREE BOND 1360K or equivalent

Torque: 137 N·m (1,400 kgf·cm, 101 ft·lbf)

6. CHECK RING GEAR RUNOUT

(a) Place the bearing outer races on their respective bearings.

Check that the right and left outer races are not interchanged.

(b) Install the differential case onto the carrier and tighten the adjusting nut just to where there is no play in the bearings.

(c) Using a dial indicator, measure the ring gear runout.

Maximum runout: 0.05 mm (0.0020 in.)

(d) Remove the differential case.

7. INSTALL DRIVE PINION FRONT AND REAR BEARING OUTER RACES

(a) Using SST and a press, install the front bearing outer race.

SST 09950-60020 (09951-00710), 09950-70010 (09951-07150)

(b) Using SST and a press, install the rear bearing outer race.

SST 09950-60020 (09951-00890), 09950-70010 (09951-07150)

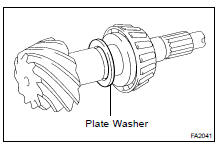

8. INSTALL DRIVE PINION REAR BEARING

(a) Install the plate washer on the drive pinion.

HINT: First fit a washer with the same thickness as the washer which was removed, then after checking the tooth contact pattern, replace the washer with one of a different thickness if necessary.

(b) Using SST and a press, install the rear bearing onto the drive pinion.

SST 09506-35010

9. TEMPORARILY ADJUST DRIVE PINION PRELOAD

(a) Install the drive pinion and front bearing.

HINT: Assemble the spacer and oil seal after adjusting the gear contact pattern.

(b) Install the oil slinger.

(c) Install the companion flange with SST.

SST 09950- 30012 (09951- 03010, 09953- 03010, 09954-03010, 09955-03030, 09956-03040)

(d) Using SST to hold the flange and adjust the drive pinion preload by tightening the companion flange nut.

SST 09330-00021

NOTICE:

- Coat the nut and screw of the drive pinon with gear oil.

- As there is no spacer, tighten the nut a little at a time, being careful not to overtighten.

(e) Using a torque wrench, measure the preload.

Preload (at starting): New bearing 1.3 - 1.8 N·m (13 - 19 kgf·cm, 11.5 - 15.9 in.·lbf) Reused bearing 0.64 - 0.92 N·m (6.5 - 9.4 kgf·cm, 5.7 - 8.1 in.·lbf)

HINT: Measure the total preload after turning the bearing clockwise and counterclockwise several times to make the bearing smooth.

10. INSTALL DIFFERENTIAL CASE IN CARRIER

(a) Place the 2 bearing outer races on their respective bearings.

Make sure that the right and left outer races are not interchanged.

(b) Install the differential case in the carrier.

HINT: Make sure that there is backlash between the ring gear and drive pinion.

11. INSTALL ADJUSTING NUTS

Install the 2 adjusting nuts on the carrier, making sure the nuts are engaged properly.

12. INSTALL BEARING CAPS

Align the matchmarks on the bearing cap and carrier. Screw in the 2 bearing cap bolts 2 or 3 turns and press down the bearing cap by hand.

HINT: If the bearing cap does not fit tightly on the carrier, the adjusting nuts are not engaged properly. Reinstall the adjusting nuts if necessary.

13. ADJUST SIDE BEARING PRELOAD

(a) Torque the 4 bolts.

Torque: 83 N·m (850 kgf·cm, 61 ft·lbf)

(b) Then loosen them to the point where the adjusting nuts can be turned by SST.

SST 09504-0001 1

(c) Tighten the 4 bolts.

Torque: 9.8 N·m (100 kgf·cm, 7 ft·lbf)

(d) Using SST, torque the adjusting nut on the ring gear side until the ring gear has a backlash of about 0.2 mm (0.008 in.).

(e) While turning the ring gear, use the SST to fully tighten the adjusting nut on the drive pinion side. After the bearings are settled, loosen the adjusting nut on the drive pinion side.

(f) Place a dial indicator on the top of the adjusting nut on the ring gear side.

(g) Adjust the side bearing to zero preload by tightening the other adjusting nut until the pointer on the indicator begins to move.

(h) Using the SST, torque the adjusting nut 1 - 1.5 notches from the zero preload position.

(i) Using a dial indicator, adjust the ring gear backlash until it is within the specified value.

Backlash: 0.13 - 0.18 mm (0.0051 - 0.0071 in.)

HINT: The backlash is adjusted by turning the right and left adjusting nuts equal amounts. For example, loosen the nut on the left side 1 notch and torque the nut on the right side 1 notch.

(j) Torque the 4 bolts.

Torque: 83 N·m (850 kgf·cm, 61 ft·lbf)

(k) After rotating the ring gear 5 turns or more, recheck the ring gear backlash.

Backlash: 0.13 - 0.18 mm (0.0051 - 0.0071 in.)

14. MEASURE TOTAL PRELOAD

Using a torque wrench, measure the preload with the teeth of the drive pinion and ring gear in contact.

Preload (at starting): Drive pinion preload plus 0.38 - 0.63 N·m (3.9 - 6.5 kgf·cm, 3.3 - 5.6 in.·lbf)

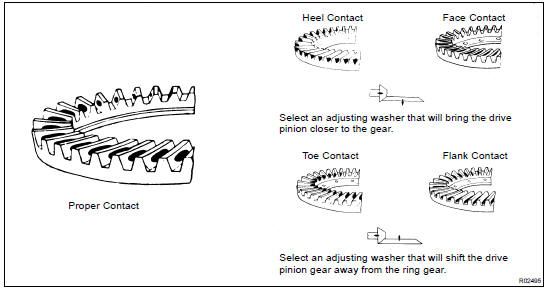

15. INSPECT TOOTH CONTACT BETWEEN RING GEAR AND DRIVE PINION

(a) Coat 3 or 4 teeth at 3 different positions on the ring gear with red lead primer.

(b) Turn the companion flange, in both directions to inspect the ring gear for proper tooth contact.

If the teeth are not contacting properly, use the following table to select a proper washer for correction.

Plate washer thickness:

16. REMOVE COMPANION FLANGE (SA-143 )

17. REMOVE OIL SLINGER AND FRONT BEARING (SA-143 )

18. REMOVE BEARING OUTER RACE

Using SST, remove the bearing outer race.

SST 09308-00010

19. INSTALL NEW BEARING SPACER

20. INSTALL BEARING OUTER RACE

Using SST and a hammer, install the bearing outer race.

SST 09316-6001 1 (09316-00011, 09316-00021)

21. INSTALL FRONT BEARING AND OIL SLINGER

22. INSTALL OIL SEAL

(a) Coat the hypoid gear oil to a new oil seal periphery.

(b) Using SST and a hammer, install the oil seal, as shown.

SST 09214-7601 1

Oil seal driven in depth: 0.5 mm (0.020 in.)

(c) Coat MP grease to the oil seal lip.

23. INSTALL COMPANION FLANGE

(a) Using SST, install the companion flange.

SST 09950- 30012 (09951- 03010, 09953- 03010, 09954-03010, 09955-03030, 09956-03040)

(b) Coat the threads of a new nut with gear oil.

(c) Using SST to hold the flange, install the nut.

SST 09330-00021

Torque: 245 N·m (2,500 kgf·cm, 181 ft·lbf)

24. ADJUST DRIVE PINION PRELOAD

Using a torque wrench, measure the preload of the backlash between the drive pinion and ring gear.

Preload (at starting): New bearing 1.3 - 1.8 N·m (13 - 19 kgf·cm, 11.5 - 15.9 in.·lbf) Reused bearing 0.64 - 0.92 N·m (6.5 - 9.4 kgf·cm, 5.7 - 8.1 in.·lbf)

If the preload is greater than the specified value, replace the bearing spacer.

If the preload is less than the specified value, retighten the nut with a force of 13 N·m (130 kgf·cm, 9 ft·lbf) at a time until the specified preload is reached.

SST 09330-00021

Torque: 441 N·m (4,500 kgf·cm, 326 ft·lbf) or less

If the maximum torque is exceeded while retightening the nut, replace the bearing spacer and repeat the preload procedure.

Do not loosen the pinion nut to reduce the preload.

25. RECHECK RING GEAR BACKLASH (SA-143 )

26. RECHECK TOOTH CONTACT BETWEEN RING GEAR AND DRIVE PINION (See step 15)

27. CHECK RUNOUT OF COMPANION FLANGE (SA-143 )

28. STAKE DRIVE PINION NUT

29. INSTALL ADJUSTING NUT LOCKS

(a) Install 2 new nut locks on the bearing caps.

(b) After tightening 2 bolts, bend the nut locks.

Torque: 13 N·m (130 kgf·cm, 10 ft·lbf)

30. REMOVE DIFFERENTIAL CARRIER FROM OVERHAUL STAND ETC.